Go watch the video first, this is just a bit of rambly context (which is unfortunately seems to be what this blog has turned into since I started to focus more on my YouTube account 😔, hopefully I’ll put out some more exclusive content on here soon)

Github:

4 Axis Polar 3D Printer: https://github.com/jyjblrd/4-Axis-Polar-3D-Printer

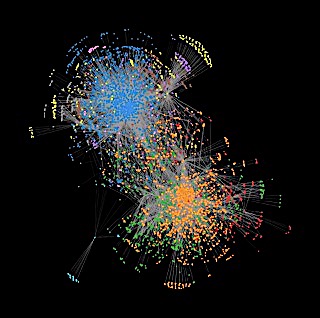

Radial Non-Planar Slicer: https://github.com/jyjblrd/Radial_Non_Planar_Slicer

Background

This project was almost entirely an accident – I never planned to design and build a 4 axis 3D printer. It starts with something almost completely unrelated: my love for ceramics. Back in high school, ceramics was probably the only mandatory art class I genuinely enjoyed. I’ve always wanted to get back into it, but studio memberships are stupidly expensive in London. I think the studio I wanted to join last summer cost almost as much as my rent in London at the time (granted, I was living out of a literal shoebox), which is pretty hard to justify given that I’m actually not that great at ceramics haha

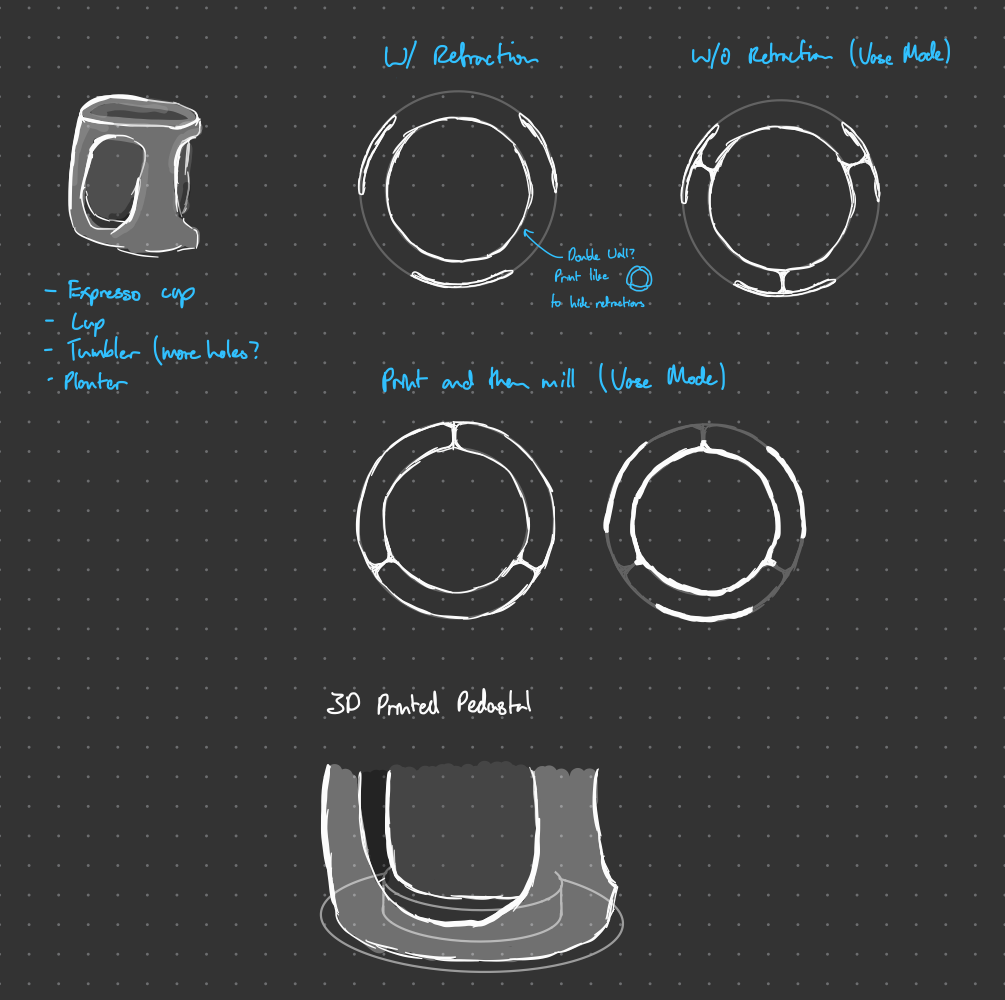

So, I decided to solve this problem by designing a ceramic 3D printer to make ceramic art for me, after all I’m a lot better at engineering and programming than ceramics! This was going to be more that just a normal ceramic printer; I also wanted it to mill the parts to carve out complex designs and smooth out the 3D printed surface. This is what led to the rotational axis on the end of the X axis, eventually spawning the whole Core XΘ idea.

My initial goal of creating a ceramic 3D printer clearly influenced the final design and is a large part of why the design is so unique – it simply has different constraints and goals to a normal 3D printer.

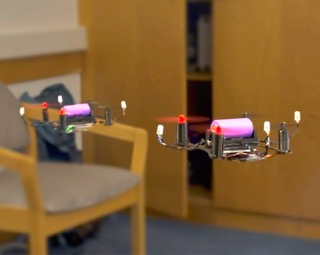

Anyway, after designing and assembling the entire printer (including the air compressor and ceramic extruder), I went online to buy some clay but could only find it in 10kg bags. I was like wait, I should probably test this before buying a literal sack of clay, so I bought the smallest extruder I could find on Aliexpress and threw it on the toolhead. It printed in normal polar mode just fine, but I always wanted to take advantage of the extra axis.

This led me down the long rabbit hole of non-planar slicing, which was a nice break from the weeks of CAD design I had previously been doing. It didn’t take long for me to realise there was a lot more potential in my non-planar slicer & 4 axis printer design than I had initially thought, leading me to shift my focus away from the ceramic stuff. Like I said in the video, there is just so much potential locked away in non-planar slicing that could instantly make even existing 3d printers way more capable than they currently are, it’s just a very complex software and algorithmic problem to solve.

One day I hope to revisit the ceramic aspect of the printer – it probably won’t bring in the same views but I would love to be able to create some ceramic art again. I initially wanted it to be done before I moved to London for my job so I could make all of my plates & cups using the printer, but that was clearly over ambitious haha.

Building the printer

A BOM is included in the github repo, but please don’t take it as a source of truth (any contributions to improve it are more than welcome!). Everything else can be printed out of PLA on any old 3D printer (I literally used the cheapest one I could find on amazon), however I would recommend the extruder mount to be printed out of either very stiff plastic or made out of metal. A PCB heat bed is also included in the repo, which should be made using an aluminum backing. If you dont need a heatbed, a simple piece of 25cm diameter MDF wood would work fine too. For the metal 3d printing and PCB manufacturing, I would recommend JLC3DP and JLCPCB respectively who I have used in the past and graciously have sponsored this project.